- Home

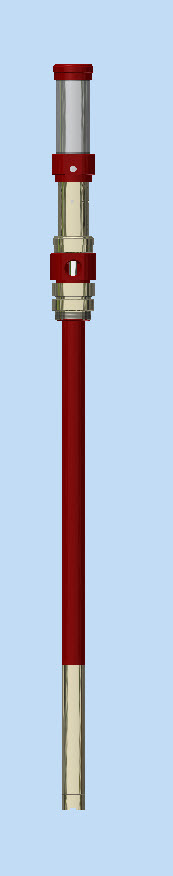

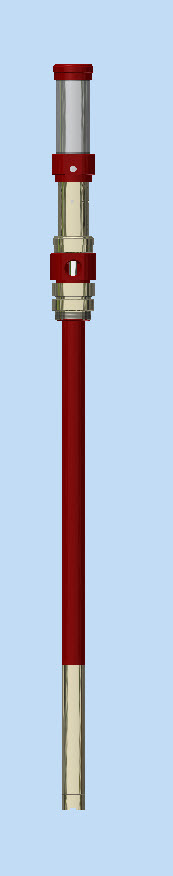

- DMIC Barrel Pump

DMIC barrel pumps are highly engineered to meet the demands of rigorous applications. Our single inlet self-reciprocating air motor drives the pump and will self-regulate speed based on inlet air pressure.

We use proprietary seals in our barrel pumps specifically designed for spray foam applications, using a special formulation to work with various compounds. The uniquely designed piston seal has multiple edges to ensure long life and durability while all shaft seals use a spring load to energize its multiple sealing edges.

DMIC’s low pressure drop design ensures maximum performance and energy efficiency starting with the inlet check valves, utilizing DMIC proprietary guided poppets instead of inferior ball checks. The media moves up the large flow chamber to the outlet instead of being forced into smaller tubes, which also helps prevent material frothing.

Another beneficial feature of the DMIC design is the ability to completely disassemble, clean and rekit when needed. Other designs have welded components that prevent cleaning out of hardened material through small tubes.

Download the spec sheet now

Download the spec sheet now

Download the spec sheet now

Download the spec sheet now

DMIC Barrel Pump